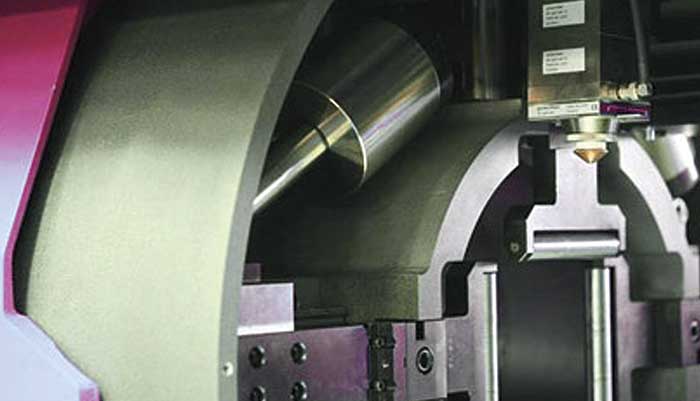

Tube Laser Cutting Systems 2d

We offer the best solutions to laser tube-cutting. Lasers can be used to eliminate whole processes while also increasing the variety of parts you are able produce.

These machines have a rock-solid cutting platform (the SL uses a minerals cast base) and offer unparalleled precision. Contoured cutting accuracy is better than +/-5um. The choice between a fiber laser and the new Monaco USP allows fine cutting of any kind of metal or polymer.